| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Sussman

Model Number : SS-GU

Certification : CCC, SGS, ISO9001, CE

Place of Origin : Wuxi Jiangsu China

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, T/T, Western Union

Supply Ability : 10 sets per month

Delivery Time : Shipped in 60 working ays after payment

Packaging Details : Standard package with film, plastic and steel wire. (or customized)

Forming speed : 12-15m/ min

Roller material : 45# Steel with quenching shaft

Control system : PLC with touch screen

Power supply : 380V, 50Hz, 3Phase

Machine weight : about 10 tons

Material : Galvanized steel sheet

Roof Gutter Roll Forming Machine

Technical Parameter

|

Item NO. |

Description |

Offered Specification |

|

1.0 | Roll forming machine | |

|

1.1 | Rolling speed | 10-15m/min(not include cutting time) |

|

1.2 | Rolling thickness | 0.3-0.6mm |

|

1.3 | Raw material | Galvanized steel sheet |

|

1.4 | dimension | 3500×1600×1500(mm) |

|

1.5 | Effective width | 60mm |

| 1.6 | Roller stations | 19 stations One stage for embossing

|

|

1.7 | Roller material | 45#forge steel, coated with chrome |

|

1.8 | Shaft diameter | Φ70mm ,material is 45# forge steel |

|

1.9 | Transmission | By chain 1 inch |

|

1.10 | Material of chain | 45# forged steel with frequency quenching, 12A |

|

1.11 | Material of cutting | Cr12Mov with quench HRC58-62° |

|

1.12 | Tolerance | 6m+-1.5mm |

|

1.13 | Frame | H type steel |

Main Components

|

No |

Name |

Quantity |

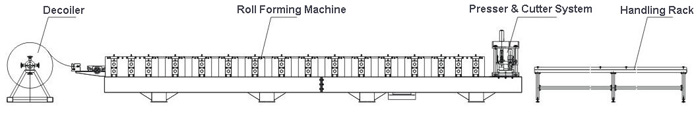

| 1 | 3 ton passive de-coiler | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Control box | 1 unit |

| 4 | Hydraulic station | 1 unit |

| 5 | Out tables | 2 units |

Working Flow

A.Passive Decoiler..........................................................To load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the heavy material.)

B.Servo Feeding Applicator............................................To feed the material accurately

C.Hydraulic/Press Punching...........................................To punch as requirements

D.Roll Forming Unit.........................................................To roll form as requirements

E.Hydraulic Cutting.........................................................To cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output Table................................................................Support the finished products

Decoiler ---- Feeding --- Levelling--- Cutting ---Roll forming--- Run out table

Profiles of Gutter

Machine Photo

Loading pictures

|

|

Touch Screen PLC Control Roof Gutter Making Machine Plate Roll Forming Machine Images |